What Is a Die Spotting Press?

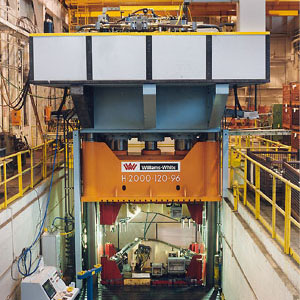

A die spotting press — sometimes referred to as a die tryout press — is a specialized hydraulic press designed for checking, testing and fine-tuning molds, dies and tools before they go into full production.

Unlike a standard forming press, a die spotting machine provides precise parallelism and controlled clamping pressure, allowing technicians to open, close and align molds / dies safely and accurately. This ensures that every Die surface mates ideally before being transferred to production equipment, minimizing defects and costly adjustments.