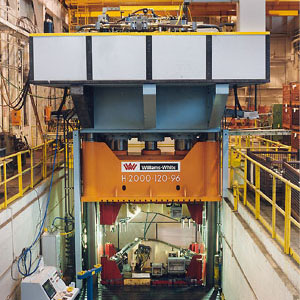

For over 170 years, Williams, White & Company has been the trusted name in engineering durable and precise hydraulic presses for the production and manufacturing industries. We custom-build each press to meet your unique operational and material requirements, delivering high-end performance, reliability, and long-term value.

For applications such as heavy-duty metal forming to composite molding, our presses are designed to provide consistent, reliable results.

A hydraulic press uses fluid pressure to generate a compressive force, allowing operators to form, shape and assemble materials with precision and control. Whether it’s drawing, bending, stamping, punching, or molding, hydraulic presses provide the essential strength and accuracy needed to excel in demanding industrial applications.

At Williams, White & Company, our presses are engineered for maximum efficiency, with integrated controls, robust frames and customizable features that ensure long-term dependability and low maintenance requirements.

Metalworking facilities across the United States trust our hydraulic presses for forging, drawing, coining and stamping operations. Engineered for precise pressure control and superior part uniformity, our presses help streamline workflows and improve output quality.

Our presses are also ideal for thermoset and thermoplastic composite molding applications, where temperature control, cycle time and precision are critical. Each press is designed to maintain uniform pressure and heat distribution, resulting in superior product consistency and performance.

Hydraulic presses are essential in the production of critical components for automotive and aerospace applications, including panels, structural supports and engine parts. Williams, White & Company presses provide the durability and precision needed to meet stringent industry standards.

For powder metallurgy, ceramics and laminating processes, our presses deliver repeatable compression and density control. This ensures part integrity, improves mechanical properties, and minimizes waste, thereby maximizing efficiency and material utilization.

Williams, White & Company specializes in custom-engineered solutions. Whether you need a press for rubber forming, plastic molding, or specialized assembly, our engineering team will design a system tailored to your operational needs and production goals.

Every single one of our presses is built to deliver long-term production efficiency through advanced engineering and durable design. Our presses offer:

When you choose Williams, White & Company, you’re partnering with over 170 years of engineering excellence.

Some of the benefits of choosing us include:

We’re proud to be the hydraulic supplier of choice for companies across North America — helping manufacturers improve precision, reduce downtime and achieve operational excellence.

Ready to elevate your production efficiency and output with a custom-engineered hydraulic press? Contact Williams, White & Company today to discuss your specific application or request a personalized quote. Let our 170+ years of expertise work for you.